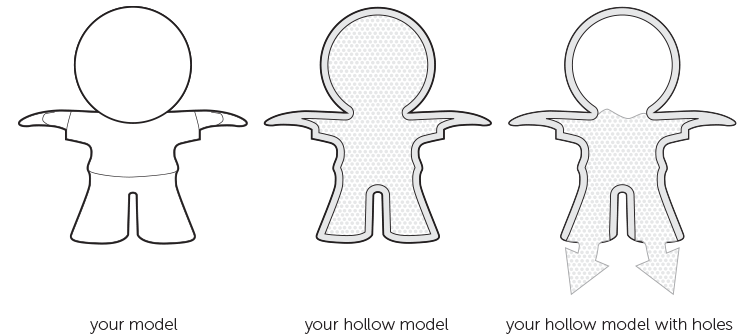

If possible, prevent enclosed volumes in your model by designing release holes as it will prevent printing material to stay stuck inside your model.

For powder based printing processes, better hollow out your model and design a strategically placed hole (two is better) so that the powder can be easily removed after printing. If there are no release holes, the powder will stay inside, making the model needlessly heavy with could result in deformation or breakage.

For resin based printing processes, the production team will be inserting release holes for the resin to escape and will fill the holes again afterwards.

More information about hollowing models